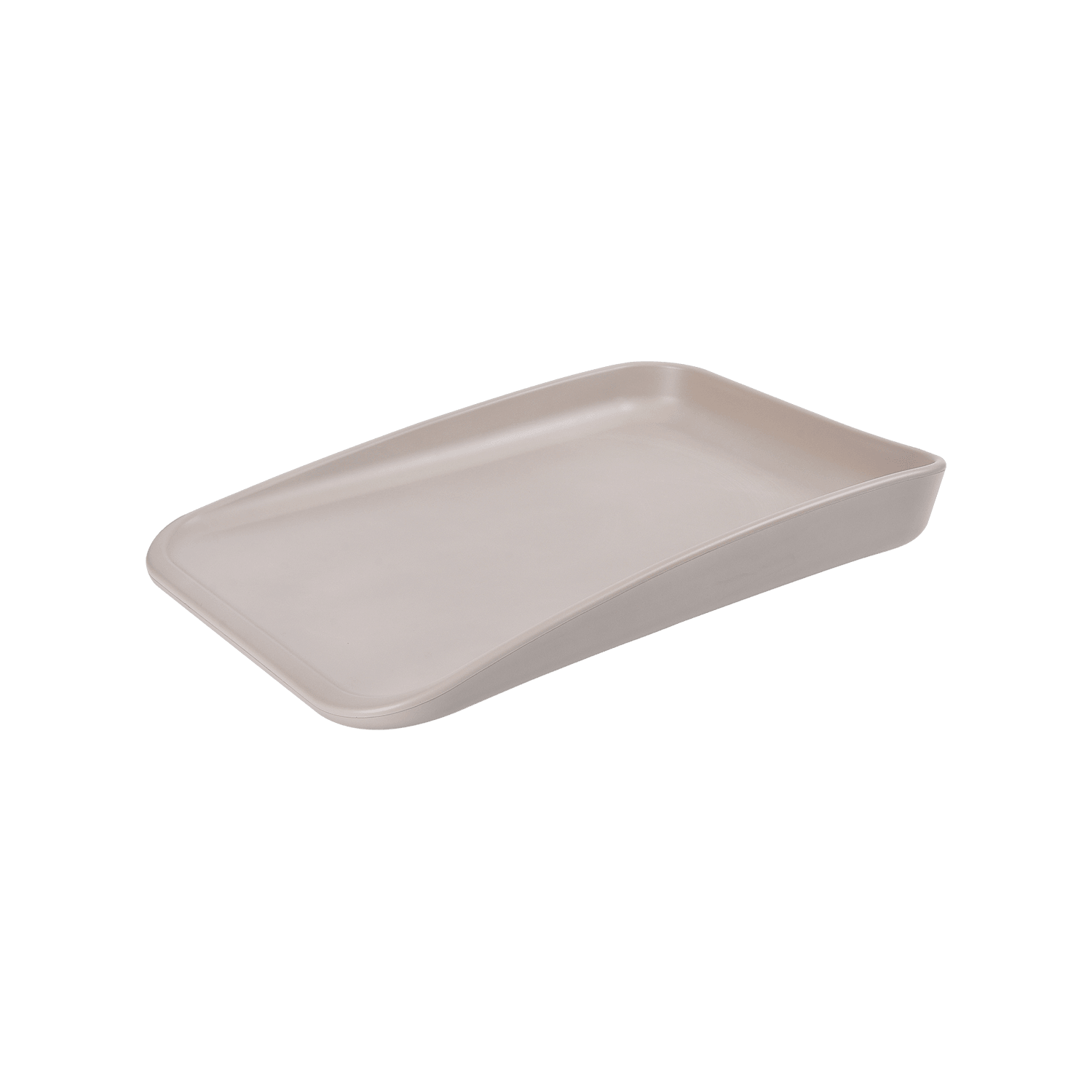

Ningbo Mianyang New Materials Co., Ltd. deeply integrates the physical properties of materials with the needs of infant care in the design and manufacture of foam changing pads. The following are the core scientific principles behind their resistance to odor or stain residue:

1. Closed-Cell Structure

Foam changing pads typically use a closed-cell polyurethane (PU) foaming process.

Principle Explanation: The closed-cell structure means that each air bubble is independent and not interconnected, forming a dense, waterproof layer on the surface.

Protective Function: This density prevents liquids from penetrating into the internal structure. Dirt, urine, and odors are difficult to enter the foam, reducing the accumulation of contaminants and the possibility of bacterial growth at the source.

2. Waterproof Coating and Easy Cleaning

As a key product in infant care, the easy-to-clean nature of the product surface is crucial.

Waterproof Properties: Ningbo Mianyang New Material Co., Ltd.'s products typically utilize waterproof PU foam, with a surface that is impermeable to water.

Easy Cleaning: This property allows diaper pads to be cleaned simply by wiping with a damp cloth, removing surface stains without deep washing and preventing residue and odors from penetrating and adhering to the surface.

3. Antibacterial and Anti-mold Additives

To ensure the safety of baby's skin, special additives are often added to the material.

Antibacterial Technology: Antibacterial agents or anti-mold agents may be added to the polyurethane foam formulation.

Enhanced Safety: This antibacterial treatment inhibits bacterial growth, thereby reducing odors produced by bacterial decomposition, allowing the foam diaper pads to remain clean and hygienic even after prolonged use.

英语

英语 西班牙语

西班牙语